Spark Plasma Sintering (SPS)

Rapid Manufacturing of Advanced Materials

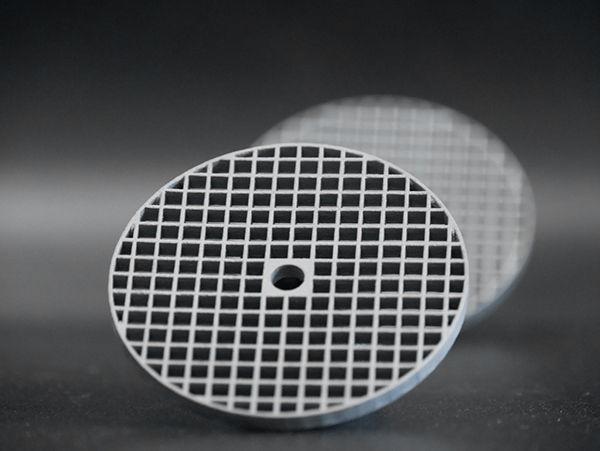

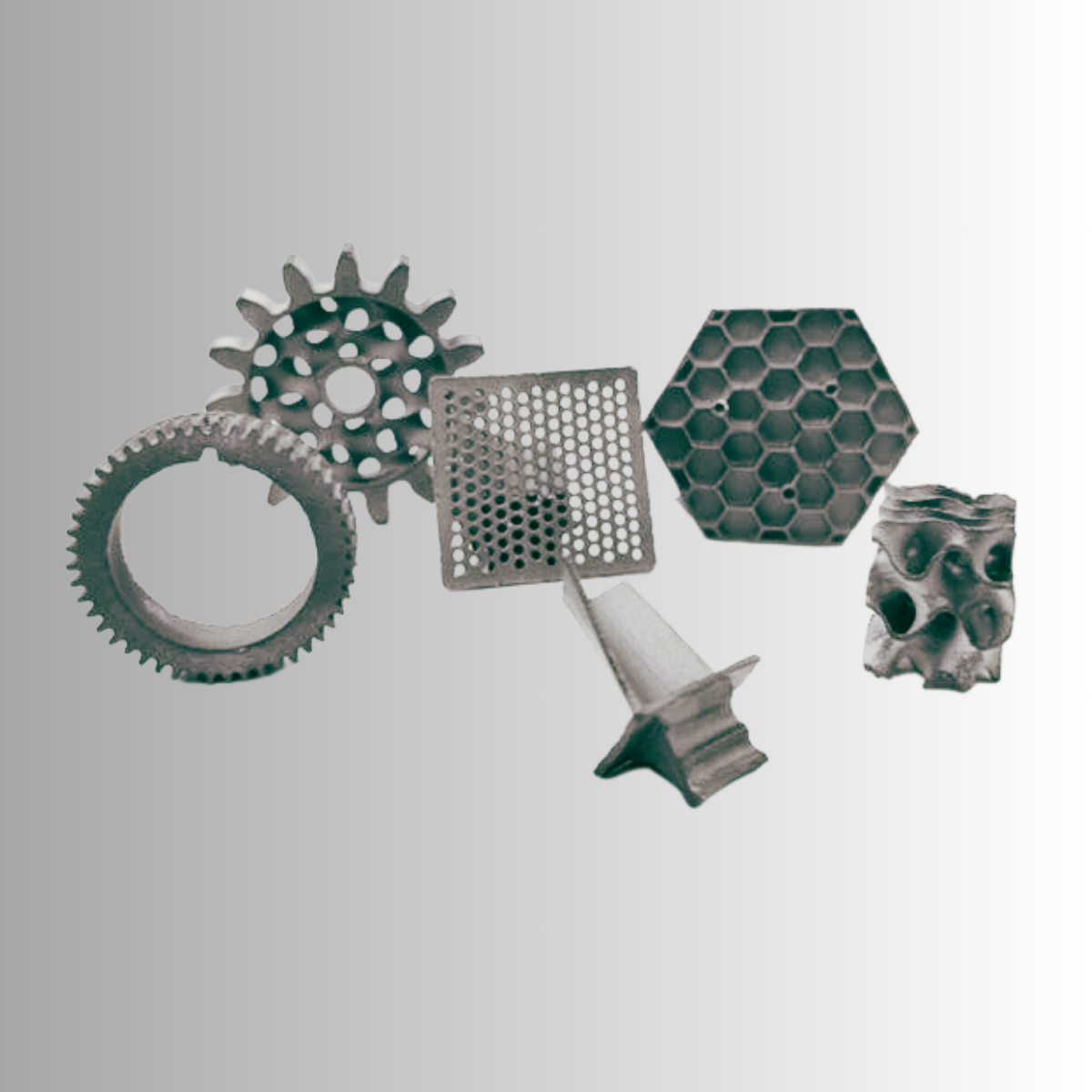

From 2D to complex 3D printing with over 99.9%

Densification SPARK PLASMA SINTERING technology experts, leveraging modeling and digitalization to produce homogeneous 2D and 3D parts with superior material properties. We can densify parts in under an hour with less than 1% porosity

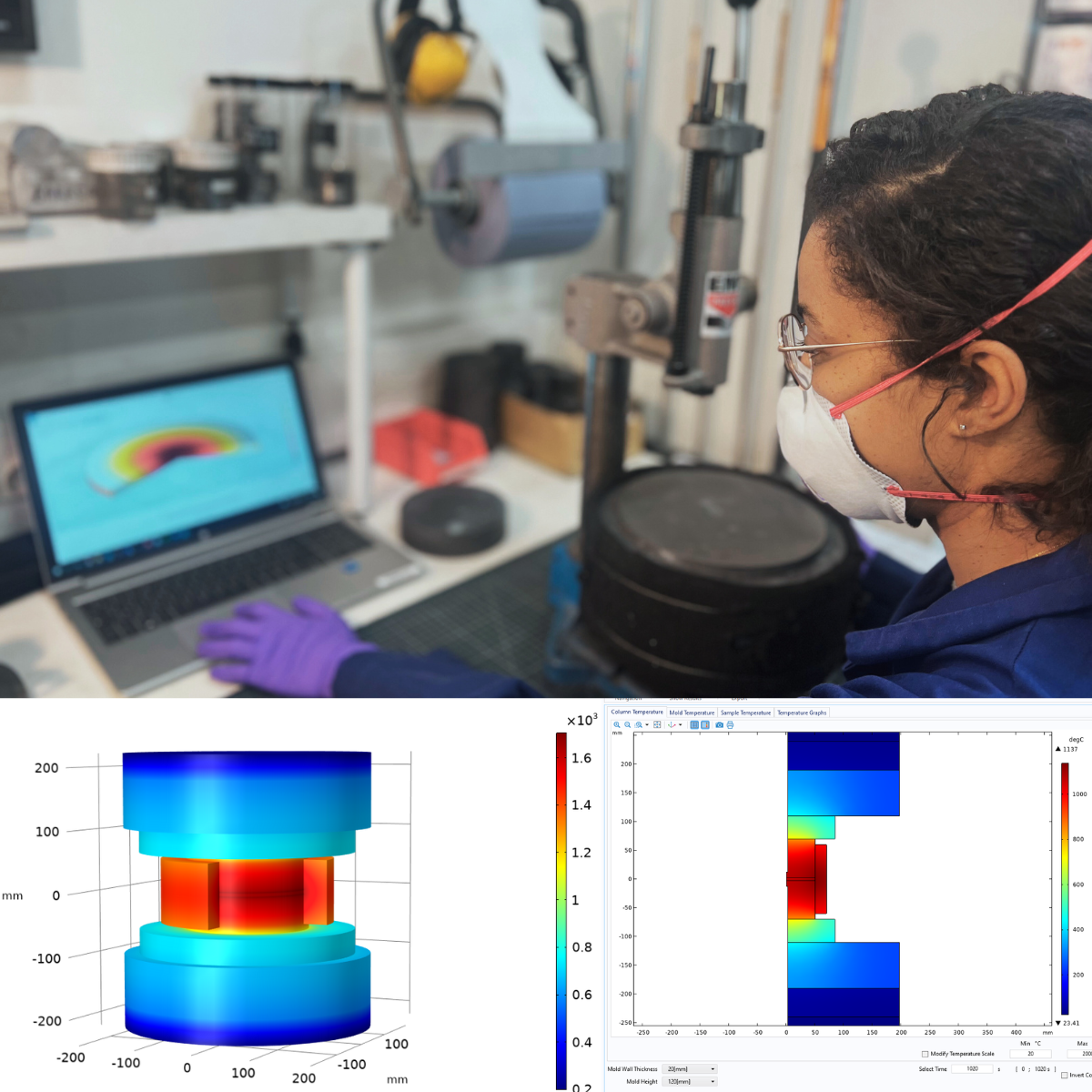

As a leading-edge sintering technology, Spark Plasma Sintering (SPS) offers unparalleled control over the densification and microstructure of materials, enabling the production of high-performance ceramics and composites. By inhibiting grain growth and achieving near-full density, SPS is ideal for processing advanced ceramics, UHTCs such as silicon carbide (SiC), and a variety of other materials

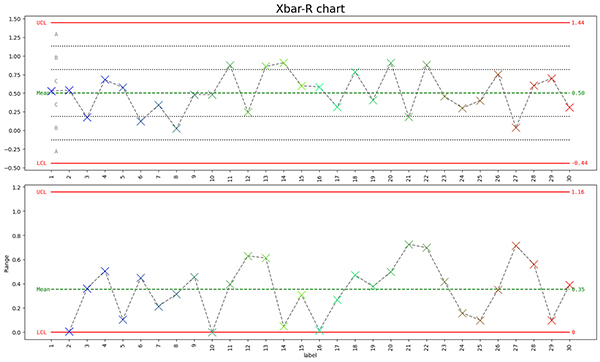

NORIMAT's innovative process sets a new standard for Spark Plasma Sintering

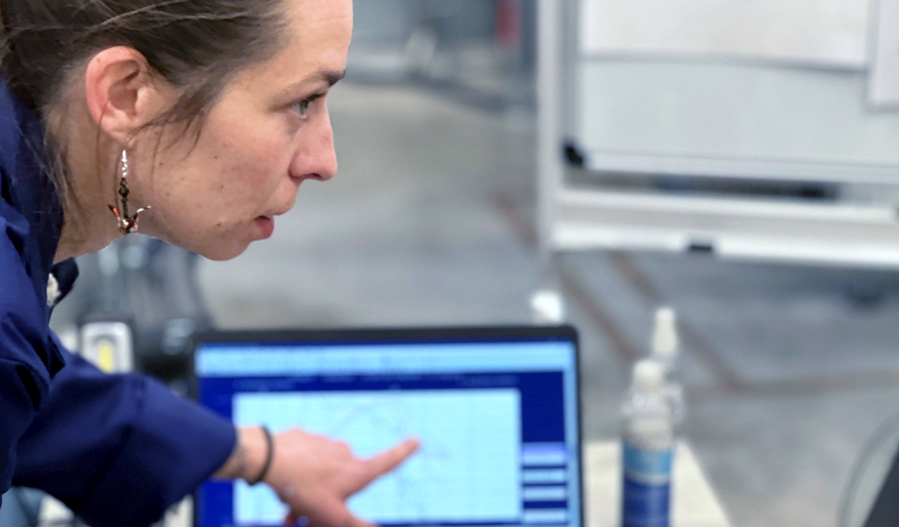

With over 20 years of Spark Plasma Sintering Technology engineering and production experience, coupled with our innovative FEA modeling, we deliver exceptional mechanical properties in your most critical and innovative parts, rapidly and for both simple and complex geometries

By sharing our Spark Plasma Sintering (SPS) technology and expertise, Norimat partners with you to develop and optimize your products, achieving complex geometries and the material performance you demand

Guided by advanced modeling, our experts transform your powders into fully dense products with the exact geometry and properties you require

UHTC - Spark Plasma Sintered Ultra-High Temperature Ceramic

Revolutionizing the Industry :

3D printing of Ultra-High Temperature Ceramic (UHTC) components, densified using Spark Plasma Sintering (SPS).

Imagine producing complex, near-net-shape parts with exceptional precision, resulting in high-quality finished components.

And that's not all! Our Spark Plasma Sintering technology allows for the rapid densification of these 3D printed parts in a single step.

Partner with NORIMAT for tailored solutions from R&D to production. Benefit from our unique expertise and dedicated support

Environmental Advantages of Spark Plasma Sintering (SPS) for Advanced Materials

LEARN MORE

MINIMAL MATERIAL WASTE

With our revolutionary FEA model, Norimat customizes solutions to meet your exact specifications.

Our team of scientists and engineers can guide you in selecting the optimal materials and designs for your components.

Unlock unlimited design freedom

3D printed UHTC components provide engineers with the flexibility to create complex and customized parts for demanding applications, such as aerospace and medical devices.