FAST/SPS FOR UHTC

Densification of SiC parts without infiltration - SBAM + FAST/SPS Sintering

A unique manufacturing technology that allows for the production of pure, 100% densified silicon carbide (SiC) parts.

Densification of SiC parts without infiltration - SBAM + FAST/SPS Sintering

NORIMAT offers a unique manufacturing technology capable of producing pure silicon carbide (SiC) parts, fully densified up to 100% within a maximum of 2 hours through hybridization of SBAM and FAST/SPS technologies. This method ensures high-quality, fully dense parts with complex shapes. With our expertise and advanced technology, we can meet the most demanding needs of our customers for their SiC parts.

ENHANCEMENT

OF MECHANICAL

PERFORMANCE

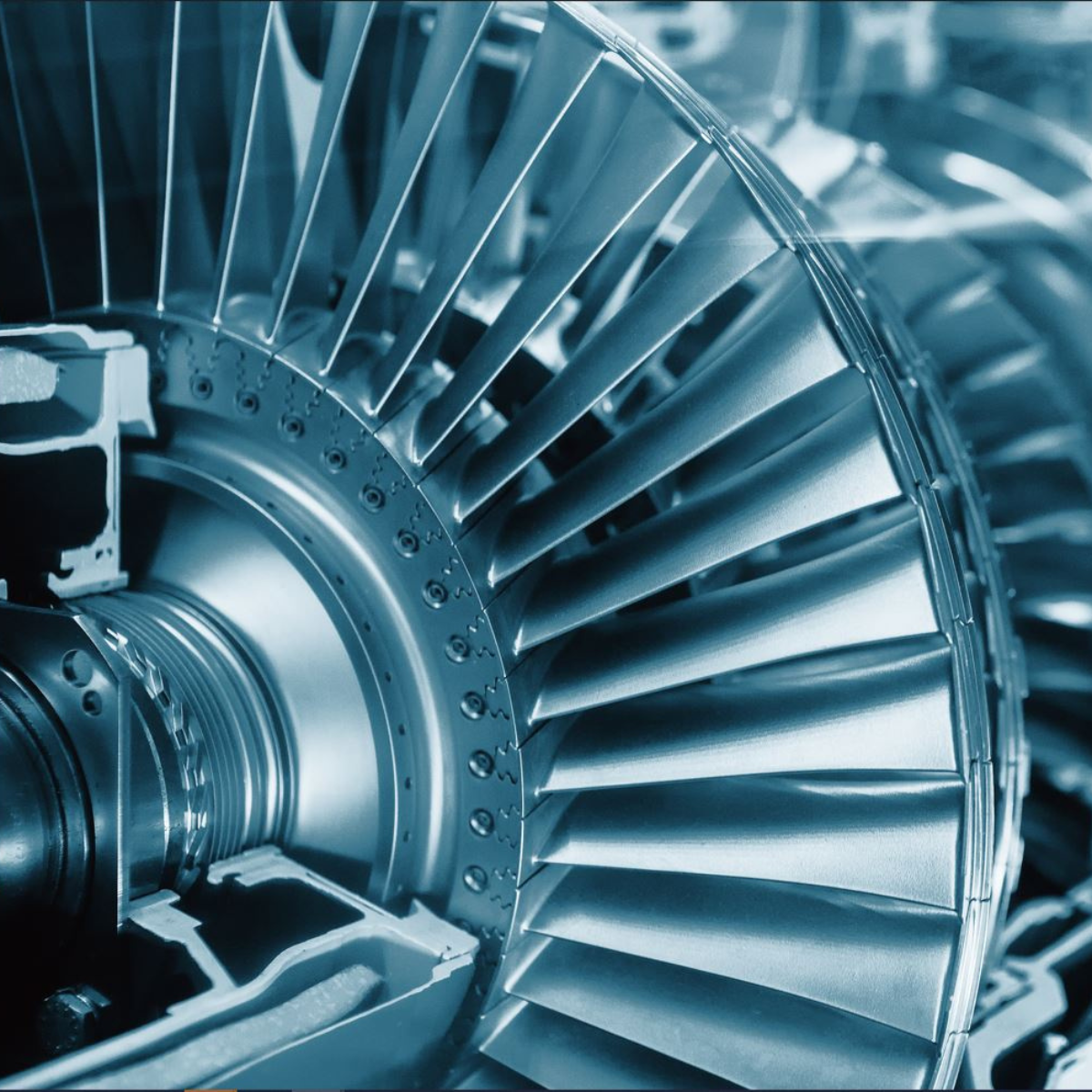

As experts in the development and production of high-performance parts from innovative materials, Norimat offers several solutions to address the challenges of the aeronautics industry.

- From powder materials to the final part in less than 1h

- Near-net shaped parts obtained (consolidation of manufacturing steps)

- Improved part performance (access to new innovative materials)

- Development of custom high-performance alloys

Hybrid Technologies SBAM and FAST/SPS

A patented process

Norimat's patented process makes it possible to produce fully dense parts in a near-net shape in less than an hour of heat treatment. The powder is transformed into a dense object in a single step, giving the final product remarkable properties without the need for post-processing. Compared to other processes (casting, conventional pressing and sintering, etc.), the total part development cycle is reduced by a factor of 4 and the material waste consumed during development is less than 1%.

This process is suitable for a wide range of metals and alloys, including intermetallics (TiAl), hard metals (superalloys) and refractory materials (carbides, UHTC, etc.). Norimat can support you from feasibility studies to mass production of high-performance parts for your aerospace applications

APPLICATIONS

- Abrasive materials

- Intermetallic alloys and superalloys

- Machining of difficult-to-machine materials

- Metallic alloys: Including intermetallic alloys (TiAl), hard metals (superalloys), and refractory materials