ENGEMINI

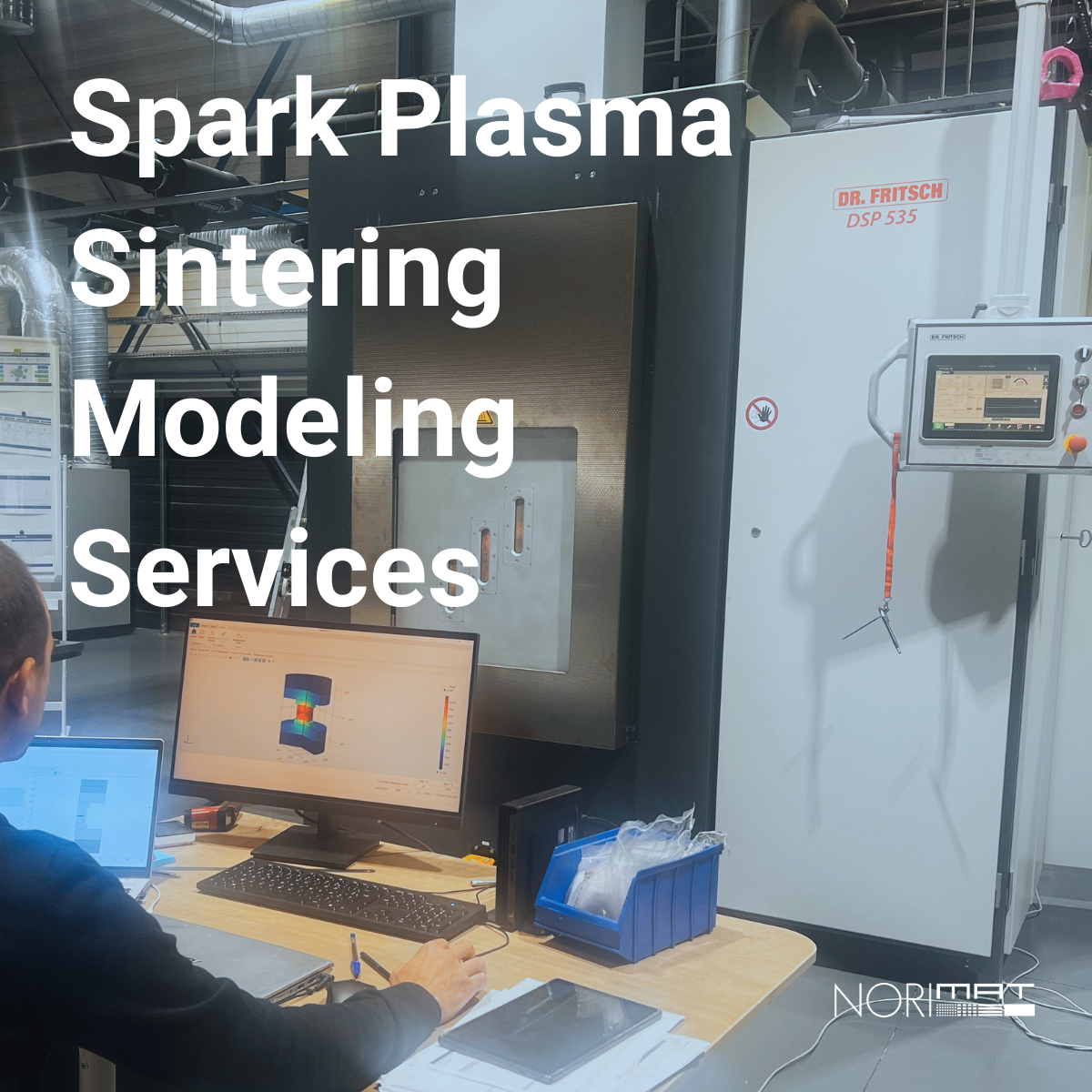

A Range of Software Solutions for FAST/SPS

Our ENGEMINI software is an innovative solution designed to help you select optimized parameters for your FAST/SPS machine. Developed to streamline your development or experimentation processes, our digital tools enable you to design the perfect FAST/SPS configuration and the associated mold to achieve your desired results.

Multiphysics Simulation

A Digital Twin of Any Flash Sintering or Spark Plasma Sintering/Field Assisted Sintering Technology Machine

Unlimited Material Experimentation

Design and Testing of Optimized Tooling Systems

Key Benefits of a Digital Twin

Predict the Thermal Homogeneity of Your Final Samplel

Digitally Simulate the Sintering Cycle for Your Specific Machine and Tool Configuration to Achieve Accurate Thermal Results for Your Materials

Control and Optimize the Manufacturing Process More Efficiently

Fully Understand the Impact of Modifying Installation Parameters, Geometries, and Material Composition of the Sample and Tool on Final Part Quality and Material Properties.

Engemini is the first and only software to offer such precise modeling of the coupled physics involved in the Spark Plasma Sintering/Field Assisted Sintering Technology (FAST/FAST) process

Design Your Tools Considering Part Quality, Tool Mechanical Constraints, Tool Cost, and Production Cycle Energy Efficiency

With Full Control Over the Geometry and Materials Used for Each Component of the Tooling (Spacers, Tools, CFC Plates), ENGEMINI Enables You to Design, Simulate, and Optimize the Perfect Tooling for Your Application.

Spark Plasma Sintering or Field Assisted Sintering Technology (FAST/SPS) Primarily Use Three Types of Molds: Graphite Molds, Metal Molds, and Composite Molds

Mold Size is Crucial for Production Cost and Part Performance. Graphite Molds are Fragile and Can Break if Not Properly Matched to the FAST/SPS Recipe and Application, Leading to Unnecessary Costs and Delays.

Depending on the Powder Quantity, Material Used, and Pressure Required for Densification, the Mechanical and Thermal Stresses on the Molds Will Vary.

These Stresses Can Easily Lead to Breakage or Poor Thermal Homogeneity, Directly Impacting the Sample and Quickly Becoming Costly.

Key Benefits of MOLD DESIGN

The Mold Design Module Enables Digital Mold Design for Spark Plasma Sintering/Field Assisted Sintering Technology (FAST/SPS), Automatically Calculating the Optimal Trade-Off Between Mold Size (Height and Wall Thickness), Energy Consumption, and Thermal Homogeneity for Any Given Material and Sample Size Combination

Increase Mold Lifespan, Achieve Parts, and Improve Productivity

Improved Thermal Homogeneity of the Sample

Optimized Dimensions

Enhanced Mold Resistance

Engemini's Mold Design Module Enhances Tool Design While Reducing Thermal Gradients Inside Your Parts

By Digitally Simulating the Thermal, Electrical, and Mechanical Physics During Your Sample's Sintering Cycle, ENGEMINI Calculates and Predicts the Optimal Graphite Mold Dimensions for Achieving the Strongest, Most Thermally Homogeneous, and Most Conductive Tooling

- Homepage

- Services

- FAST-SPS-Modeling-and-Digital-simulation