- Homepage

- Services

- PROTOTYPAGE

Benefits of Choosing Spark Plasma Sintering (FAST/SPS) for Manufacturing High-Performance Parts

Norimat: Turnkey R&D, Prototyping, and Serial Production Services for Your Industrial Projects

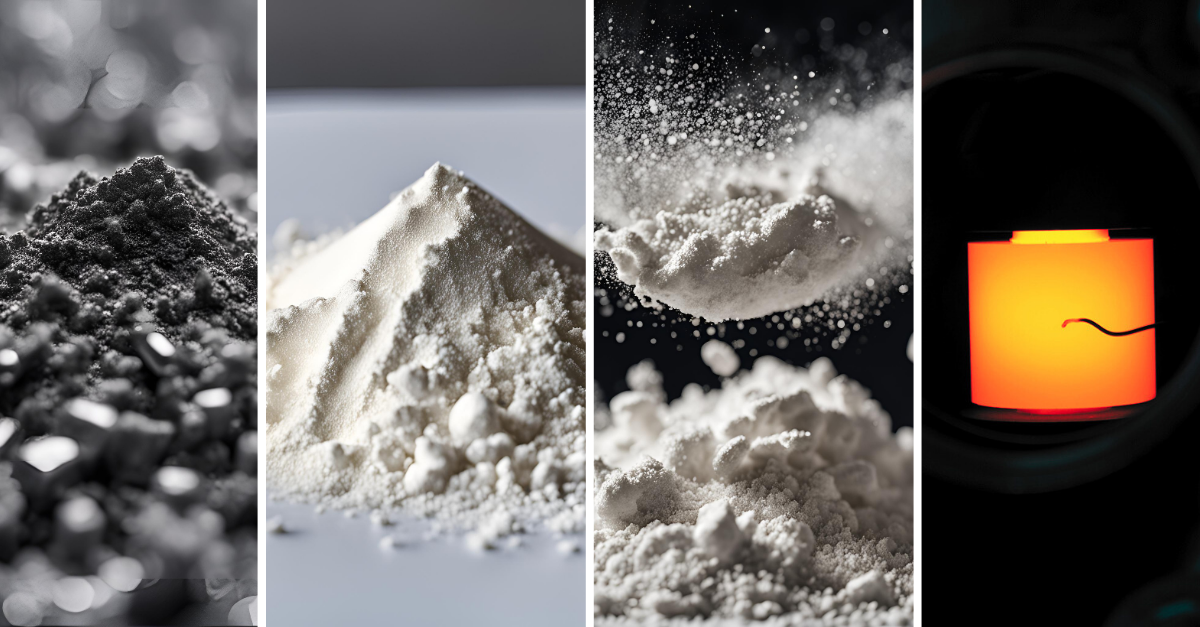

Spark Plasma Sintering (SPS) is a cutting-edge technology used to manufacture solid, dense, and homogeneous materials from powders. This process involves applying a pulsed direct current (DC) and uniaxial pressure to the powder inside a mold. The current passes through the powder, resulting in rapid heating and efficient sintering. SPS is typically carried out in a vacuum or controlled atmosphere to prevent oxidation and ensure material purity. Temperature, pressure, and heating rate are carefully controlled throughout the process, enabling the production of materials with unique microstructures and properties.

Material Design, Engineering, and Qualification Services

- Collaborative R&D in Powder Metallurgy

- Material Design and Development for FAST/SPS Sintering

- Advanced Material Modeling for Spark Plasma Sintering (SPS)

- Sintering Process Simulation

- Geometry Optimization for Additive Manufacturing and SPS Sintering

- Powder Supply by Client or Norimat

- Optimization of SPS Sintering Conditions for High-Performance Materials

- Sample Production for SPS Testing and Validation

- Mechanical Performance and Microstructure Analysis of Sintered Materials

- Quality Control, Performance, and Characterization According to Specifications

- Serial Production of Spark Plasma Sintered Components

Turnkey R&D, Prototyping, and Serial Production Services by NORIMAT

As experts in the development and production of high-performance parts from innovative materials, Norimat offers a range of solutions to address industrial challenges, from material design to final part production in under one hour. Through the optimization of manufacturing processes, we produce near-net-shape parts, enhancing performance by providing access to new innovative materials and developing custom high-performance alloys.

Powder Metallurgy: Revolutionize Your Parts with Spark Plasma Sintering (FAST/SPS)

Specification Definition, Feasibility Study, Material Development and Optimization, Prototyping, Validation, Pilot Production, and Serial Manufacturing to Meet Industrial Market Demands

Norimat, Expert in High-Performance Part Development and Manufacturing with Innovative Materials, Offers Advanced Solutions for Industry Challenges

- Homepage

- Services

- PROTOTYPAGE