- Homepage

- Matériaux

Industry 4.0: Spark plasma Sintering, a Boost for Your Products

Looking to develop cutting-edge materials?

Spark Plasma Sintering (SPS) is the ultimate solution for rapid production of high-performance parts. Also known as Field Assisted Sintering Technology (FAST), SPS offers a revolutionary approach to densify a wide range of materials (metals, ceramics, composites) by simultaneously applying uniaxial pressure and pulsed electric current. Experience unparalleled speed and precision in your materials production.

METALS AND ALLOYS: YOUR COMPREHENSIVE GUIDE TO INDUSTRIAL MATERIALS. DISCOVER A WIDE RANGE OF METALS INCLUDING STAINLESS STEEL, ALUMINUM, COBALT, NICKEL, TITANIUM, AND COPPER.

Looking for high-performance materials for your project? Our comprehensive guide introduces you to the main metals and alloys used in industry.

Stainless Steel

Corrosion-resistant stainless steel is essential in food processing, medical, and chemical industries.

Aluminum Alloys

Lightweight and strong, aluminum alloys find applications in aerospace, automotive, and electronics.

Cobalt-based Alloys

Resistant to high temperatures and boasting high hardness, cobalt-based alloys are used in energy, aerospace, and industrial applications.

Nickel-based Alloys

Corrosion and high-temperature resistant, nickel-based alloys are used in the chemical, energy, and aerospace industries.

Titanium Alloys: Biocompatible, lightweight, and corrosion-resistant, titanium alloys are used in surgery and the aerospace industry.

Copper and its Alloys

Excellent conductors of heat and electricity, copper and its alloys are indispensable in electronics and the electrical industry.

High-Entropy Alloys (HEAs) offer exceptional mechanical properties due to their complex composition. Combined with Spark Plasma Sintering (SPS), they enable the creation of dense and homogeneous parts in record time, paving the way for new applications in aerospace, automotive, and energy sectors.

UHTC

Ultra-high-strength materials

Printing and densification

99.9% density

Detailed work

Minimal post-processing

Advanced Ceramic Materials Development

Colors

TECHNICAL CERAMICS: UNLOCKING THE POTENTIAL OF REFRACTORY MATERIALS WITH SPS

Technical ceramics offer exceptional properties that make them ideal for a wide range of industrial applications. Through the Spark Plasma Sintering (SPS) process, dense and high-purity ceramic components can be produced in record time.

Oxides

Alumina (Al2O3) and zirconia (ZrO2) are the most commonly used oxides. Their hardness, toughness, heat resistance, and electrical insulation make them ideal for high-temperature applications such as thermal coatings and industrial furnace components.

Carbides

Silicon carbide (SiC) and boron carbide (B4C) are ultra-hard ceramics with excellent thermal and chemical stability. They are used in demanding applications such as brakes, cutting tools, and armor. Tungsten carbide (WC), as well as titanium, tantalum, and zirconium carbides, are also highly valued for their extreme hardness, wear resistance, and resistance to temperature and compression. They are used in the manufacture of cutting tools, molds, and mechanical components subjected to high stress.

Revolutionize your industry with sustainable, high-performance

SPS, an advanced sintering technique, enables rapid production of dense, fine-grained materials with exceptional properties.

NITRIDES AND COMPOSITES: HIGH-PERFORMANCE MATERIALS FOR DIVERSE INDUSTRIES

Nitrides are advanced ceramics offering exceptional mechanical, thermal, and chemical properties. Their unique characteristics make them ideal for demanding applications across various industries.

Silicon Nitride (Si3N4)

Known for its thermal shock resistance, low thermal expansion coefficient, and high mechanical strength, silicon nitride is used in engine components, ball bearings, and extreme environments like aerospace and energy.

Aluminum Nitride (AlN)

With high thermal conductivity, excellent electrical insulation, and chemical stability, aluminum nitride is primarily used for thermal management in electronics, such as semiconductor chips and LEDs.

Titanium Nitride

Titanium nitride is valued for its exceptional hardness and low coefficient of friction, making it ideal for cutting tools and wear parts in high-temperature environments.

Composites

Combining the best of both worlds, metal-ceramic and ceramic-ceramic composites offer enhanced properties for demanding applications. Metal-ceramic composites provide increased strength and abrasion resistance, while ceramic-ceramic composites offer improved impact and fracture toughness.

Applications

Aerospace, Automotive, Electronics, Bomedical, and energy.

Norimat: Your Partner for Custom, High-Density Materials

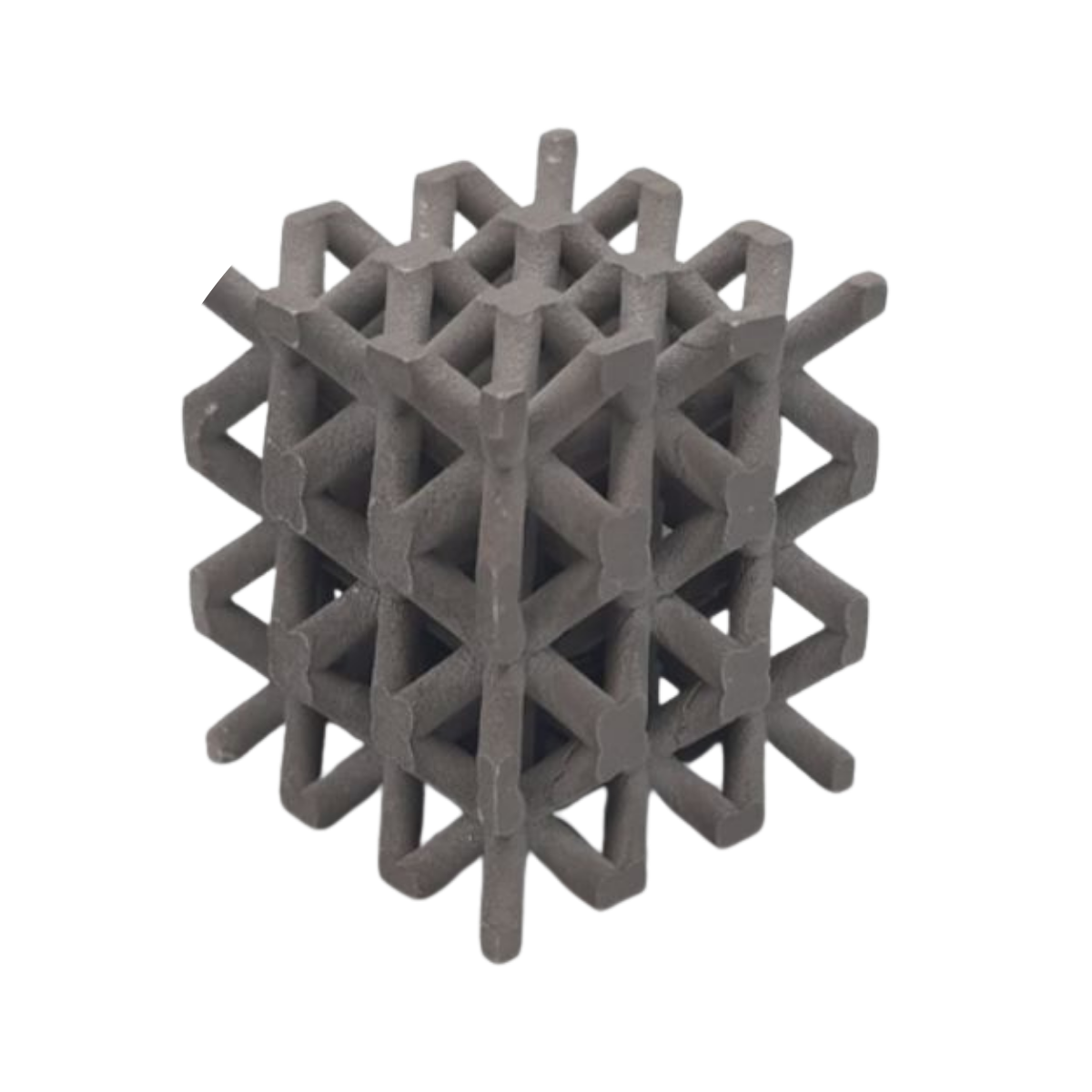

3D printing is unlocking the potential of silicon carbide, a super-strong material that has been hard to work with in the past. Our innovative process allows us to create complex silicon carbide parts with near-perfect density, opening up a world of new possibilities. From smartphones to spacecraft, silicon carbide is the future of materials science. With our technology, we're making this remarkable material more accessible than ever before.

- Homepage

- Matériaux