An eco-responsible technology

- Homepage

- Spark Plasma Sintering

Spark Plasma Sintering (SPS) Fast: The Ultimate Guide to Advanced Materials Manufacturing

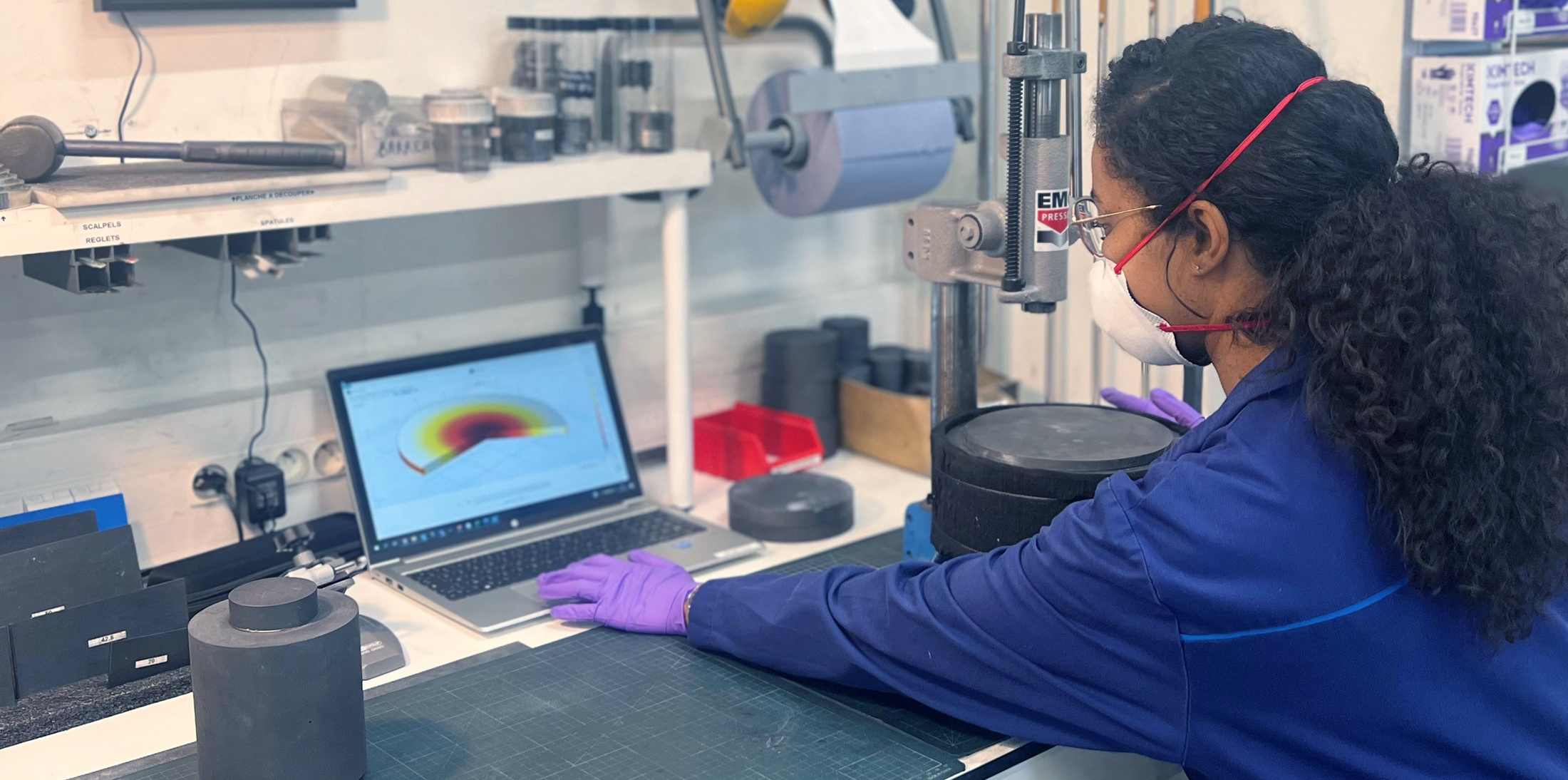

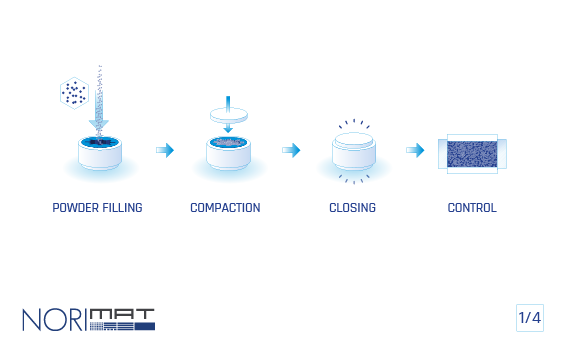

Spark Plasma Sintering (SPS) / FAST is a revolutionary powder metallurgy technique that leverages electric current to rapidly sinter materials at elevated temperatures and pressures. This process offers numerous advantages over traditional sintering methods, including shorter processing times, higher densities, and improved microstructural control. SPS/FAST is widely applicable to a broad range of materials, from ceramics and metals to composites and nanomaterials.

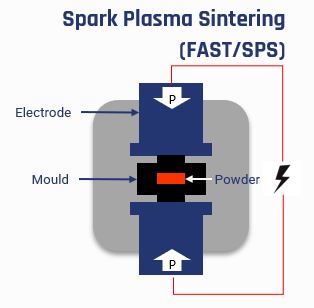

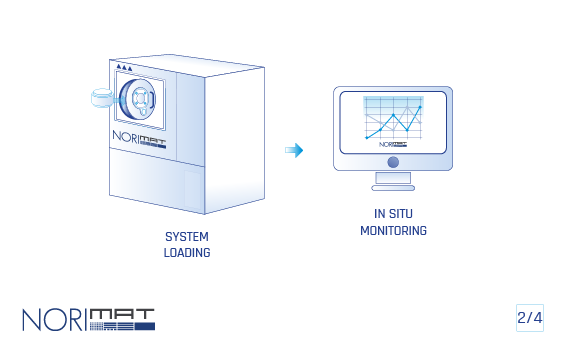

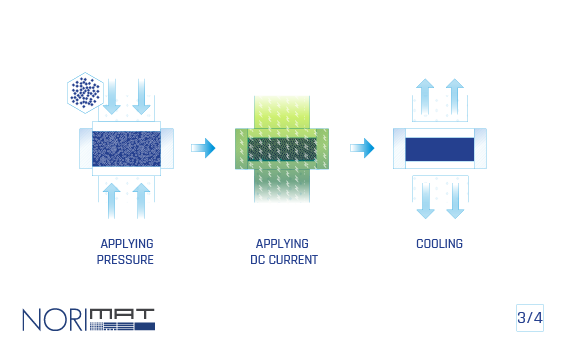

How does SPS work? By applying a combination of high pressure and pulsed direct current, SPS heats powders rapidly and uniformly, leading to near full densification in less than an hour. This rapid heating and sintering process results in materials with exceptional properties, including high purity, fine grain size, and tailored microstructure.

SPARK PLASMA SINTERING (FAST/SPS)

Spark Plasma Sintering (SPS): High-Speed, High-Purity Materials Fabrication

SPS delivers unmatched heating and cooling rates, surpassing 100°C/min. Compared to conventional sintering techniques, SPS drastically reduces processing time, achieving high temperatures in minutes instead of hours. This accelerated sintering process enhances production efficiency.

Material Purity and Homogeneity

One of the primary advantages of SPS is the absence of organic binders, commonly used in other sintering processes. This feature ensures the purity of the final material and minimizes defects that can compromise its properties.

Reduction of Residual Stresses

By precisely controlling the thermal gradient during the process, SPS minimizes residual stresses in finished parts, significantly enhancing the durability and reliability of materials.

Spark Plasma Sintering (SPS): How Pulsed Current Revolutionizes Manufacturing

Optimized mechanical properties through fine microstructure

The short cycle time and rapid heating rate of SPS promote the development of a fine and homogeneous microstructure. This characteristic results in significantly improved mechanical properties of sintered materials, such as hardness, strength, and toughness.

Wide-ranging applications across industries

The benefits of SPS make it an indispensable technology for the fabrication of innovative and high-performance materials. Whether for composites, hard metals, metal alloys, or refractory materials, SPS offers a flexible and efficient solution.

Discover Norimat's cutting-edge FAST/SPS process. With our unique 3D printing capabilities, we create complex parts with unmatched precision and superior mechanical properties.

Our FAST/SPS rapid sintering process enables the production of near net shape metal parts, significantly reducing machining operations and material waste. This approach is particularly advantageous for the manufacturing of functional prototypes or series production of complex parts

All the Benefits of Spark Plasma Sintering: Discover how this innovative process can enhance your materials.

Ultra-fast manufacturing cycle: From powder to finished part in under an hour with SPS

High-speed sintering: Experience heating rates over 100°C/minute for superior results

Substantially improved mechanical properties

SPS enables near-full density (up to 99.5%) and preserves fine microstructure, leading to superior mechanical properties like hardness, toughness, and fatigue resistance. Ideal for applications demanding high performance

Minimize waste, maximize efficiency: Less than 1% material waste

Near-net-shape, fully dense components: Minimize material waste and achieve optimal properties

Dense a variety of materials within a broad temperature range (200°C to 2400°C)

Spark Plasma Sintering (SPS) excels at sintering the most innovative and refractory materials

Your Partner for Advanced Spark Plasma Sintering, Driving Innovation

NORIMAT: Your partner for advanced materials. From prototyping to full-scale production, we provide unparalleled expertise in Spark Plasma Sintering (FAST/SPS).

Our team specializes in custom manufacturing of complex, innovative parts, from highly refractory micro-powders to alloys and composites